The Economist wrote an analysis: If the mainland "martial arts" Taiwan Province, the West may not dare to sanction China like Russia.

[Text/Observer Network Xiong Chaoran] "Does the United States really dare to freeze or even confiscate China’s official reserve assets?" Last month, Wang Yongli, former vice president of Bank of China and a senior researcher at Chongyang Financial Research Institute of Renmin University of China, asked this question in an article he wrote.

This is indeed a good question, especially after the conflict between Russia and Ukraine, the United States and its allies imposed severe sanctions on the Russian central bank, making about half of its foreign exchange reserves unusable. The West also cut off some large Russian banks from the western financial system and banned many high-tech products from exporting to Russia.

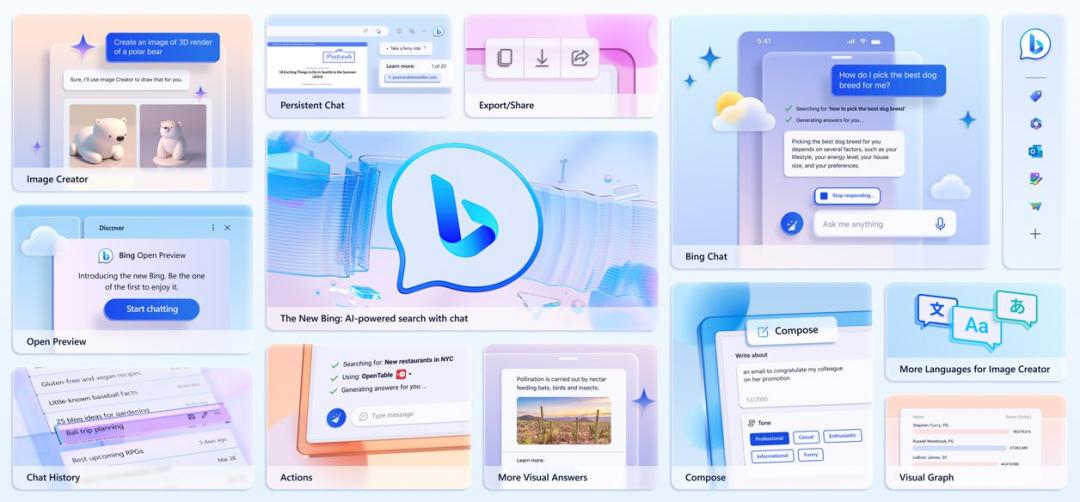

In the latest issue of The Economist, published on April 23rd, local time, the magazine interviewed many experts and scholars, and analyzed and discussed this question-if China acts at the geopolitical level, such as the mainland’s "Wu Tong" Taiwan Province, will the west treat China like Russia?

According to the article, most experts agree that it is impossible for western countries, led by the United States, to seriously damage China, the world’s second largest economy, while their own financial systems and trade markets are not seriously damaged. Therefore, for this reason, the West may "be afraid to go that far".

Screenshot of The Economist report

The article first quotes Eswar Prasad, a professor at Cornell University in the United States, saying that "the United States and its allies certainly have ways to deal with China". He believes that at present, the power center of global finance is still firmly occupied by the West, and two-thirds of China’s $3.2 trillion foreign exchange reserves may be western government bonds, and the United States and European countries can freeze these assets when necessary.

"But do western countries really dare (freeze assets)?" Subsequently, this article in The Economist immediately raised such a question. According to the article, freezing China’s foreign exchange reserves may not cause too much instability. China can find other ways to fight back, and the large amount of assets held by westerners in China will also be worrying.

Gerard Pi Bo, a senior researcher at the Center for International Strategy and Studies (CSIS), pointed out that in return, China could confiscate foreigners’ assets in China. By the end of last year, foreigners had $3.6 trillion in direct investment in China, including fixed factories and $2.2 trillion in stocks, bonds and other "portfolio" investments, which was six times as much as the equivalent assets held by foreign countries in Russia.

Data Map: Employees of a foreign trade enterprise in Pingxiang Logistics Park of China-ASEAN Free Trade Area are producing exported electronic products.. Photo from Xinhua News Agency

"What if the West also imposes sanctions on financial institutions other than the Bank of China?" The Economist has considered this question again, and the answer is that this may make western institutions face "financial backlash".

According to the data of the Financial Stability Board (FSB), an international financial regulator, among the 30 banks with "specific systemic importance" in the world, 4 are China banks. If these banks are attacked, it may harm the interests of western institutions that provide loans to them or open accounts there.

Clay Lowery of the International Finance Association (IIF), a bankers’ organization, said that he was "not confident" about whether western countries had the confidence to cut off the business of China banks in order to keep their financial stability undisturbed.

The article points out that if the West adopts these sanctions against China, it will also cause serious damage to trade. Last year, less than one-fifth of China’s trade was settled in RMB, and most of the rest was settled in US dollars.

Martin Chorzempa, a senior researcher at the Peterson Institute for International Economics in the United States, said: "Without insurance and trade credit, many economic activities will dry up. Since China is a major trading partner of more than 120 countries, this kind of destruction may turn the rest of the world against the United States and its allies. "

According to the article, China accounts for 18% of the total imports of the United States and more than 22% of the total imports of the European Union, including many parts used in domestic manufacturing. Therefore, blocking trade with China may harm the country’s own production, including its exports.

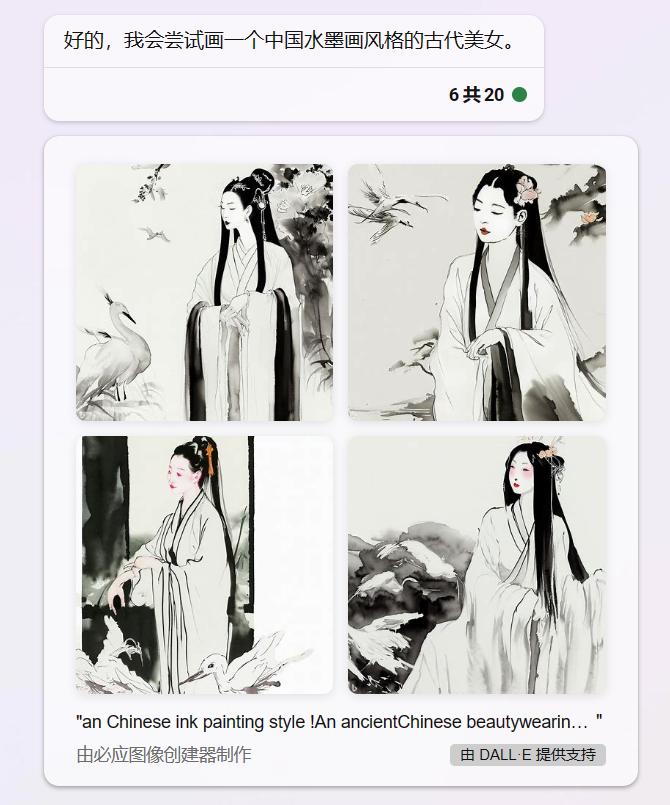

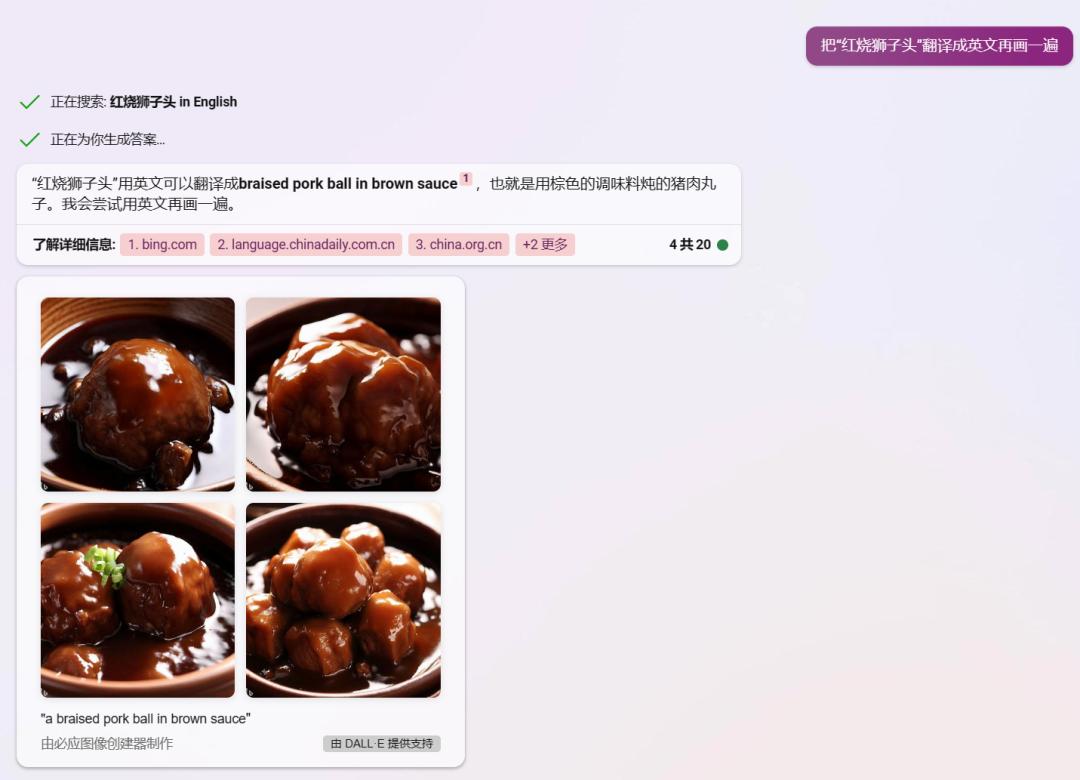

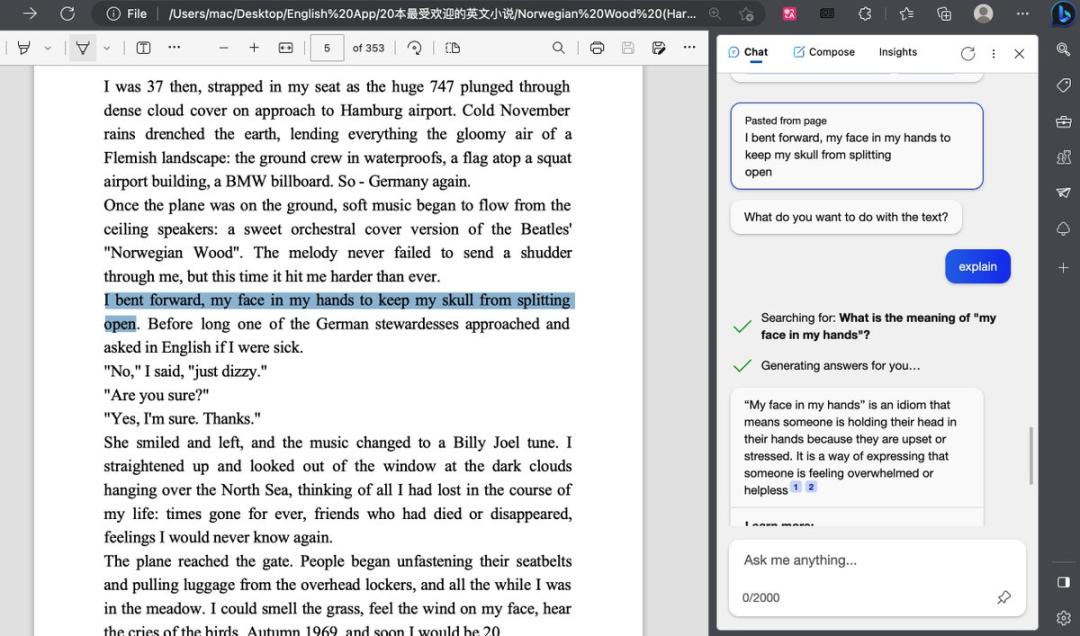

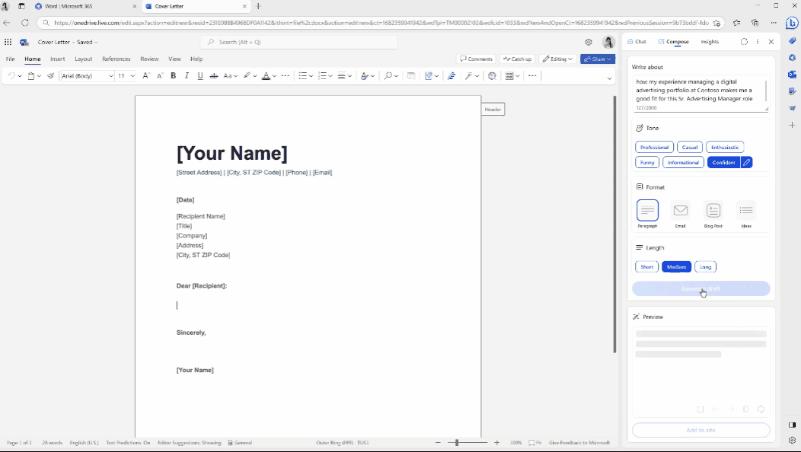

The proportion of parts and components of electronic and electrical products imported from China in 2020 is shown in The Economist.

According to the simulation calculation of Gabriel Felbermayr, a professor at Vienna University of Economics and his co-authors, if the United States and its allies cut China’s imports by more than 90%, its own exports will drop by nearly 10%.

Western experts believe that China’s most important influence comes from its vast market. The United States may want to deprive China of some high-tech R&D, such as semiconductors, but according to the data of Boston Consulting Group (BCG), a total ban on semiconductor production will cost American semiconductor companies 37% of their income and endanger more than 120,000 jobs.

At the end of the article, it is said that the West can strike Russia harder economically whenever Russia tries to fight back, but this may not be the case for China, which in turn will make China fight back. For example, as far as China is concerned, the export restriction of rare earth can be used as a tool, and rare earth is used in many electronic products, which may disrupt the supply chain of other manufacturing segments of electric vehicle battery boxes.

"Then, if the United States and its allies impose the same sanctions on China as on Russia, they may suffer considerable pain. For this reason, they may not dare to go that far, but they certainly hope that China will not find out. " The article draws such a conclusion.

This article is an exclusive manuscript of Observer. It cannot be reproduced without authorization.